Telephone:13851008208

Fax:0515-83810696

Mail box:18651208006@126.com

Website:en.baisidekj.com

Address:Building 7, No. 1, Jianshe East Road, Changzhou high tech Zone, Dafeng City

Production method of pressure gas nitriding multi-purpose furnace

The pressure gas nitriding multi-purpose furnace includes a furnace body, the furnace body includes a pressure bearing tank body, a heating element, a heating nitriding chamber in the pressure bearing tank body, a cooling system outside the pressure bearing tank body; the inner wall of the pressure bearing tank body is provided with a fire-resistant heat preservation layer, the wall of the heating nitriding chamber is the fire-resistant heat preservation layer, the heating element is installed in the fire-resistant heat preservation layer On the warm layer. In the prior art, in order to improve the hardness, wear resistance, corrosion resistance other properties of the surface layer of metal workpiece, nitrogen atoms are infiltrated into the surface layer of steel by the chemical heat treatment process of nitriding. There are many kinds of nitriding methods, gas nitriding ion nitriding are two commonly used methods.

At present, gas nitriding method is widely used in production, with stable process performance good nitriding effect. The specific process is as follows: put the metal workpiece into the sealed heat-resistant steel tank, introduce flowing nitrogen ammonia gas, etc., heat keep the temperature for a long time, then the nitrogen ammonia gas will decompose to produce active nitrogen atoms, which will be continuously adsorbed on the surface of the metal workpiece, diffuse into the metalworker In the surface layer of the workpiece, the chemical composition structure of the surface layer are changed to obtain excellent surface performance. The sealed steel tank is usually made of heat-resistant steel. When the heat-resistant steel is at above 560 ° C, the mechanical property drops sharply. At this time, the pressure of nitrogen ammonia in the heat-resistant steel tank cannot be too high, especially more than 0.01 MPa (0.1 kg). Because the nitriding speed quality are related to the pressure of ammonia gas ammonia gas in the heat-resistant steel tank, the chemical heat treatment process of nitriding takes a long time (about 70-80 hours), which seriously affects the economic benefits of the enterprise.

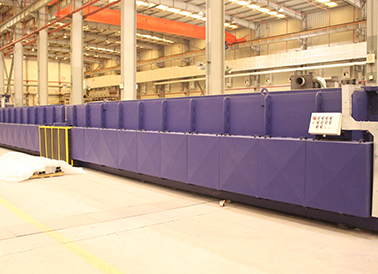

The utility model provides a pressure gas nitriding multi-purpose furnace which can shorten the nitriding chemical heat treatment process time, so as to solve the technical problem that the nitriding process takes a long time in the prior art improve the nitriding process efficiency of the heat treatment enterprise. In order to solve the above problems, the utility model adopts the following technical scheme: a pressure gas nitriding multi-purpose furnace, including a furnace body, the furnace body including a pressure tank body, a heating element, a heating nitriding chamber located in the pressure tank body, a cooling system located outside the pressure tank body; the inner wall of the pressure tank body is provided with a fire-resistant insulation layer, the wall of the heating nitriding chamber is The fire-resistant heat preservation layer, the heating element is installed on the fire-resistant heat preservation layer. The pressure gas nitriding multi-purpose furnace, the cooling system includes a circulating water jacket wrapped on the outside of the pressure bearing tank body, cooling circulating water is arranged in the cavity between the inner wall of the circulating water jacket the outer wall of the pressure bearing tank body; the circulating water jacket is provided with a cooling circulating water inlet a cooling circulating water outlet connected with the fluid in the cavity. The pressure gas nitriding multi-purpose furnace has a thickness of 5-15 cm for the fire-resistant insulation layer. The pressure gas nitriding multi-purpose furnace has a thickness of 5-8 cm for the refractory insulation layer. The pressure gas nitriding multi-purpose furnace is a vertical furnace a horizontal furnace. The pressure gas nitriding multi-purpose furnace, the heating nitriding chamber is respectively connected with the fluid at the inlet of the nitriding agent the outlet of the waste gas on the furnace body. The utility model relates to a pressure gas nitriding multi-purpose furnace, a pressure gauge is arranged on the exhaust gas outlet. The utility model can shorten the chemical heat treatment process time of nitriding, solve the technical problem that the nitriding process takes a long time in the prior art, improve the nitriding process efficiency of the heat treatment enterprise; moreover, the utility model can also be used for the vacuum gas quenching, realize the multi-purpose of one thing, reduce the equipment cost of the heat treatment enterprise, improve the utilization rate of the production equipment of the enterprise.

The above is the multi-purpose furnace production line manufacturers to introduce to you the relevant content, I hope to have something for you.

Address: Building 7, No.1, Jianshe East Road,

Changzhou high tech Zone, Dafeng City

Telephone:138-5100-8208

Mailbox:18651208006@126.com

Scan pay attention to us