Telephone:13851008208

Fax:0515-83810696

Mail box:18651208006@126.com

Website:en.baisidekj.com

Address:Building 7, No. 1, Jianshe East Road, Changzhou high tech Zone, Dafeng City

Controlled atmosphere stick type bainite martensite quenching furnace

The isothermal annealing production line of roller hearth furnace with front rear vacuum lock chambers in baisde can fully meet the requirements of spheroidizing isothermal rapid annealing of large batch of bearing parts, bars plates of non-ferrous metals ferrous metals by means of isothermal annealing process.

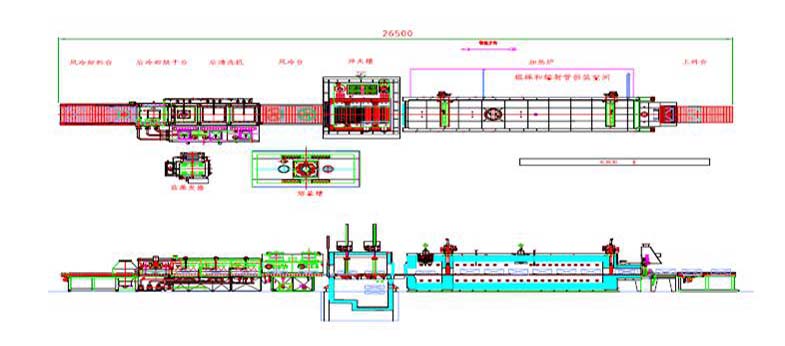

The production line of martensite quenching cooling after cleaning in roller furnace with controllable atmosphere is used for heat treatment of bearing ring parts, which is composed of roller feeding platform, roller heating furnace, roller salt bath quenching tank, air cooling platform, roller post cleaning machine, secondary cooling drying, production line electrical temperature control system, computer monitoring system, etc.

The production line of roller hearth salt bath quenching furnace with controllable atmosphere is mainly used for austempering of large medium-sized bearings such as rolling mill bearings, railway bearings, etc. salt bath martensite classification quenching.

Can provide various solutions according to different needs of customers

Features of the production line: salt bath quenching is adopted. Many years of practice have proved that salt bath quenching can ensure the hardenability hardenability of the workpiece, at the same time, the cooling is even. It can be used for the martensite classification quenching of bearing steel at any temperature of 150-300 ℃. Effectively solve the quenching quality problems of products with large wall thickness easily deformed products.

Salt bath quenching is used to solve the problem of unstable gold caused by the failure of quenching tank.

Serial number | Specification type | Throughput | Square dimension | Passing height | Heating furnace station | Tempering furnace station |

1 | BSD 750/750/150-6 | 300kg/h | 750×750 | 150 | 6 | 26 |

2 | BSD 750/750/150-7 | 350kg/h | 750×750 | 150 | 7 | 30 |

3 | BSD 750/750/150-8 | 400kg/h | 750×750 | 150 | 8 | 34 |

4 | BSD 750/750/150-9 | 450kg/h | 750×750 | 150 | 9 | 38 |

The protective atmosphere roller hearth furnace heat treatment production line is mainly used for bright quenching, tempering tempering of large quantities of bearing rings, rolling elements, various fasteners, small annular parts, etc. It has the characteristics of zero collision, zero decarburization small deformation.

The bearing parts are placed on the feeding table (pad the wire mesh in the material tray), automatically enter the front cleaner according to the process cycle for immersion, spray drying. The dried workpiece automatically enters the roller heating furnace according to the cycle, enters the hot oil tank for quenching after being heated to the temperature according to the process requirements. After quenching, the workpiece enters the secondary cooling tank for secondary cooling, then enters the rear washing machine for soaking, spraying, the cleaned workpiece enters the tempering furnace for tempering. After tempering, the workpiece enters the unloading platform for unloading after cooling by the air cooling platform.

Address: Building 7, No.1, Jianshe East Road,

Changzhou high tech Zone, Dafeng City

Telephone:138-5100-8208

Mailbox:18651208006@126.com

Scan pay attention to us